Figuring out what was what

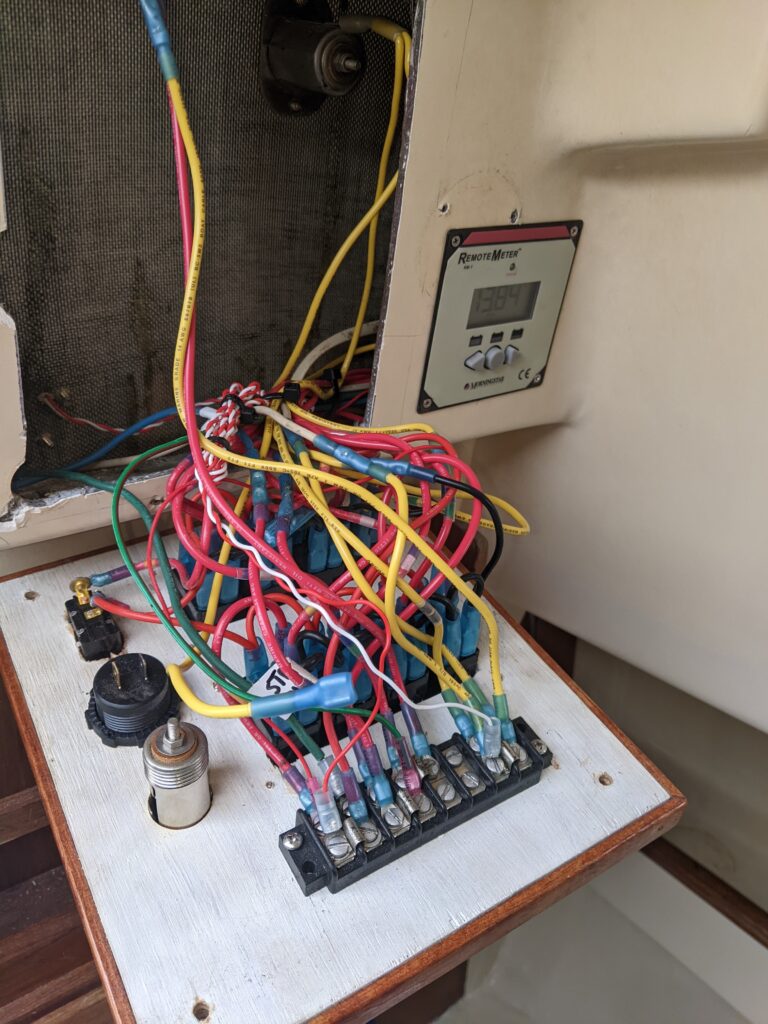

This boat seems typical of most old small sailboats. Electrical needs were simpler back in the 1970’s, and systems weren’t built for expansion and extra gadgets like they are in some modern boats. On our boat, the switch panel was small, and the cabinet behind it was also very small. A previous owner decided to use the space under the companionway step as a new area to run wires and mount equipment. He ran wires from the main 4-switch panel to terminal blocks under the step, and mounted two batteries in boxes in the lockers on each side of the step. In a small boat, this took up precious space in the cabin compartments, and the batteries were sitting at angles and loosely secured to the boat with nylon straps and plastic clamps.

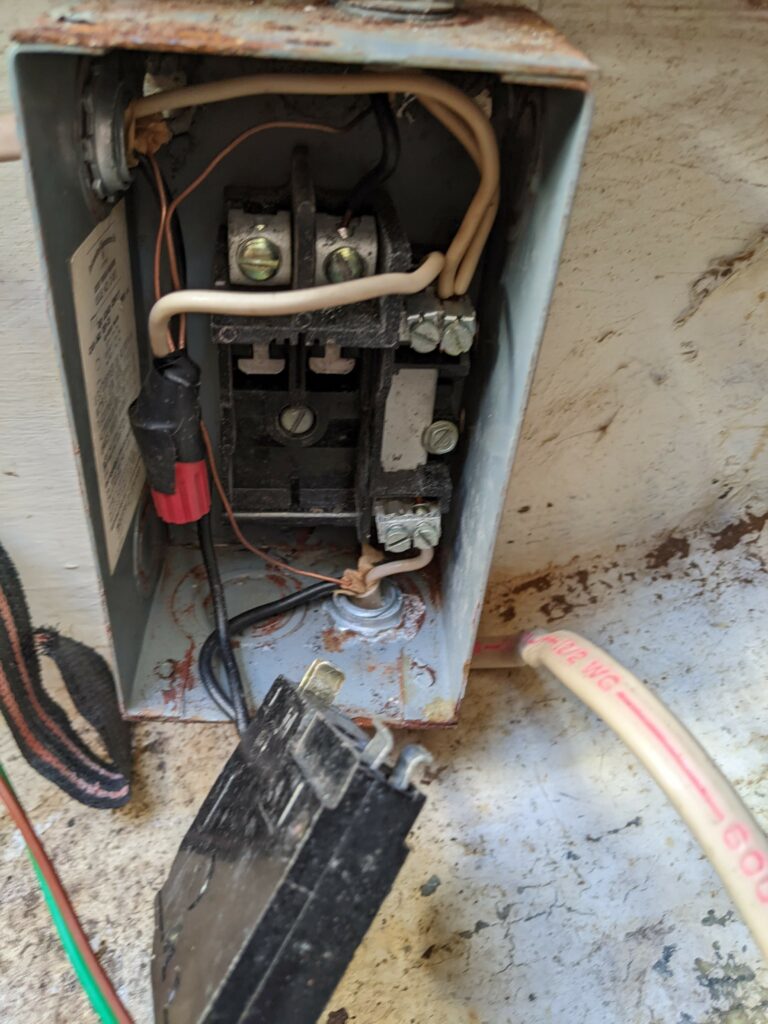

With this setup, most of the wiring was within inches of the bilge water and the companionway opening. As a result, most of the connections were severely corroded–but surprisingly, almost everything worked.

Making a Plan

When rewiring a boat, it’s probably best to rip all the old stuff out and replace everything with new wires, switches, fuses, etc. However, I decided to keep some of the existing wiring and electronics to save time and money. The Sailstar and Bristol 26 were built with a liner on the cabin ceiling, which makes replacing those wires difficult. Luckily all of those wires were only for cabin lighting, so I decided to leave their old wiring in place and redo the connections I could reach.

The other, more recent wiring installed by previous owners was easily accessible since it wasn’t installed under any type of liner. I was able to reroute and organize it better, getting it out of places like the top of the quarterberth, the tops of lockers where it can get damaged, and the bilge areas.

The Layout

I decided to cut the area around the existing switch panel to provide better access to that area, and to maximize the space available for switches. I built a plywood cover and mounted two rows of 4 switches on it. On the front side of the board, I also mounted a switch that controlled the panel lights (I didn’t want them to be on all the time), a DC outlet, and a USB outlet. On the back of the new cover, I mounted a bus bar to use for the lighting connections.

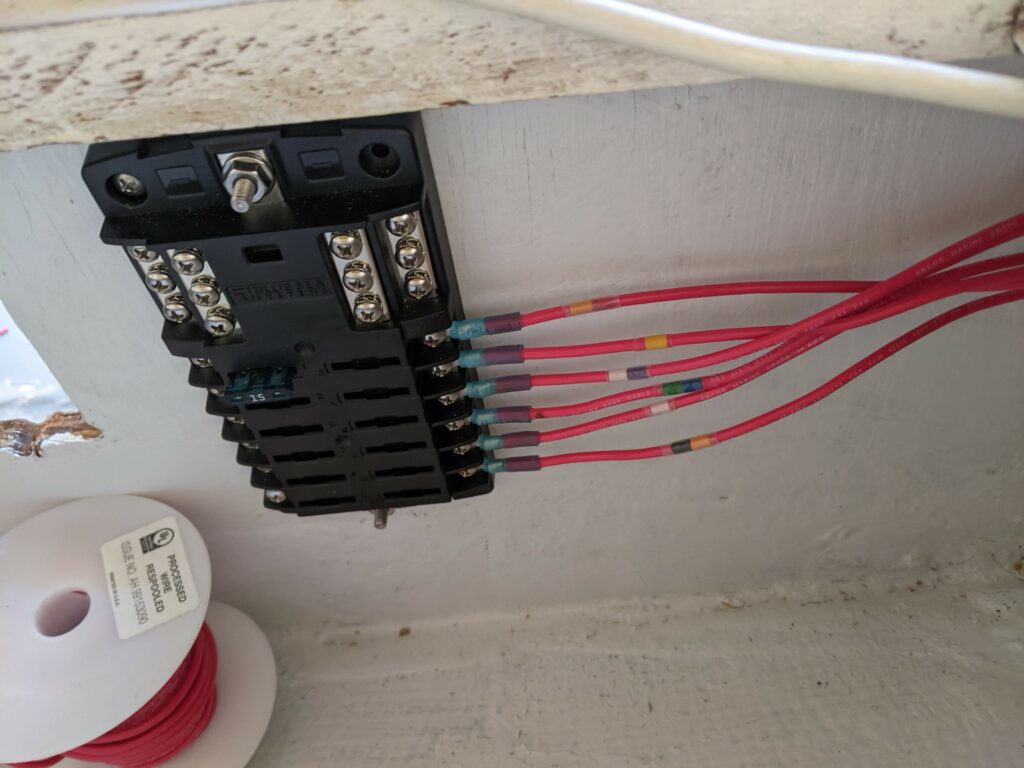

The new switches didn’t have breakers built into them, like the original ones did. I decided to mount two “Blue Sea” brand fuse blocks in the small storage locker in the middle of the dinette area on the port side of the boat. It’s a dry locker isolated from the bilge, and it’s shallow and offers limited storage. I thought it would be a good dry location to mount the majority of the electrical system. I also liked the fuse blocks, which allowed me to customize the fuse sizes according to the needs of the system. A lot of the switch panels I looked at had 15 amp circuit breakers, and were much more expensive than the setup I decided to use.

Moving the wiring out from under the companionway step freed that area up, so I bought two AGM batteries and mounted them in that area. It’s close to the boat’s centerline, and the AGM batteries are sealed, so they don’t need to be enclosed in boxes. I cut some thick plywood strips and secured the batteries with one of these strips along with some stainless brackets.

Finding a Good Stopping Point

Once I completed the bulk of the DC wiring, I decided to wrap up the project and enjoy the boat for the summer. I also figured that I used up the budget for boat repairs/improvements for the season. The new batteries were wired in, fuse blocks worked good, and everything was much more organized, safe, and secure. All the switches that were located in random places on the boat were all moved to one location at the switch panel And, by moving the batteries, I freed up two storage lockers.

My updated “to-do” list:

- Install two new LED light assemblies in the V-Berth.

- Install a small inverter and switch/circuit breaker. This will be wired so it can be disconnected when using shore power.

- Replace the old AC outlets. I already removed the solid home store wiring and corroded steel boxes. I’ll install plastic boxes and stranded wire to the new ones.

- Replace the solar panel. The existing 80-watt one works but is about 20 years old, and takes up a lot of space at the stern. I plan to install a 50-watt panel on a pole in the stern to free up space. The electrical system is simple on this boat, so hopefully this panel will be big enough. If not, I may add a second panel.

- Add a bilge pump to the motor well. I already ran the wiring for the pump. I just need to design and install a small sump to collect the water and to mount the pump in.

Thanks for Reading, and Come Back Soon for Updates!

Interested in more information?

Would you like me to work on your boat or other project? Or, do you just have some questions or want more information about this project?

If so, feel free to contact me using the “send me a message” form on the homepage, or by emailing me at joe@overthereef.com.